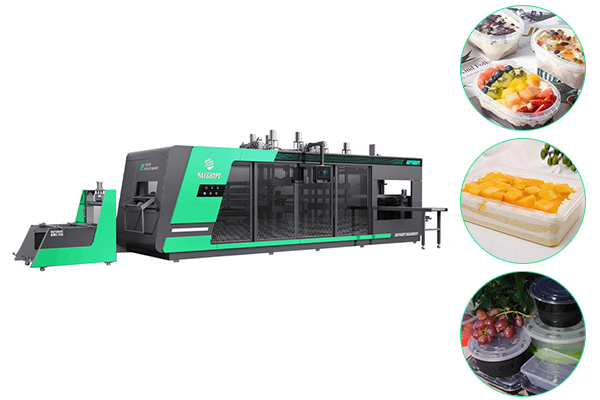

ELEMOTION's Plastic Thermoforming Machine utilizes internationally advanced plastic sheet forming technology. It integrates mechanical, pneumatic, and electrical design, automatically completing all sheet forming processes to ensure continuous sheet forming.

High degree of standardization, complete functions, safe, efficient, energy-saving and hygienic.

It integrates mechanical, pneumatic and electrical integration, and is controlled by microcomputer and programmable controller (PLC).

Easy-to-operate human-machine interface, and has the function of remote connection.

Electric lifting, double-station large-diameter unwinding, allowing a single person to load coils weighing up to 600KG.

Servo feeding, stepless adjustment of sheet length, high speed, accuracy and stability.

The upper and lower electric heating furnaces are used for four-stage heating and protection to reduce the impact of air convection on temperature, so that the product molding is stable, from 0-400 degrees in just 3 minutes, improving production efficiency. The electric heating furnace can automatically remove the device.

A new real-time distributed digital dynamic hot forming temperature control system is used to control the temperature of the tile at a single point, and it has automatic compensation control, with an accuracy of ±1℃. Energy saving of about 15% and extended furnace plate service life.

Q:

What is the capacity of the thermoforming machine?A:

The accurate capacity depends on the size and material of the products.Q:

What kinds of products can the thermoforming machine produce?A:

It can produce all kinds of disposable plastic cup lid, bowls, plate, boxes, egg tray, food container, etc.Q:

Do you have different models for each machine?A:

Yes, we have different models and we can make the machine according to your requirements.Q:

What is the production time?A:

Normally we need around 45 working days.We have a 30-person after-sales team

30-day fast delivery, modular production

One-year warranty, lifetime maintenance

GET A QUOTE