Upper Forming Depth: 100mm

Bottom Forming Depth: 130mm

Forming Area: 730*610mm

Width Of Sheet: 400-800mm

The Longest Knife:10m

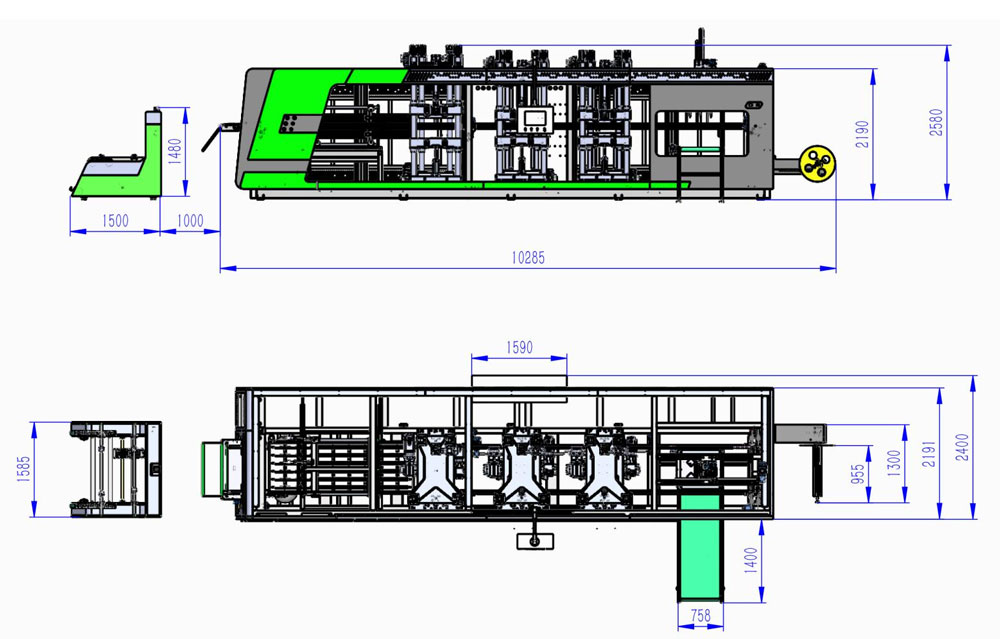

Machine size: 12785*2350*2700mm

RS-730-610-4 positive and negative pressure multi-station plastic thermoforming machine, uses internationally advanced plastic sheet forming technology. It is a plastic sheet forming equipment with mechanical, pneumatic and electrical integrated design. It can automatically complete all actions such as loading, feeding, heating, forming, punching, cutting, stacking, finished product transportation, and edge material winding.

It is suitable for processing different materials, such as A-PET, R-PET, C-PET, BOPS, HIPS, PP, PLA, PVC and barrier materials, processing high transparency, high stretch, shallow stretch, round, square, upper and lower two-way stretch, flanged and other products, including trays, lids, fruit and vegetable boxes, flower pots, shells, seedling trays and plates, etc.

It can make some products which unable to be made in one station thermoforminging machine, like for example: PLA products, plastic lids or containers which has holes, the packing containers (fruit box, egg trays) with body and cover connected etc.

Features and Advantages

Machine Structure

Essential Component

|

Loading sheet part:

Load automatically, lower human resource cost.

Proximity switch clever control, getting the rid of falling down of the sheet by conveying too fast.

Double stations, big diameter, reduce the frequency of changing sheet coil, improve the the production efficiency.

Max undertake roll of sheet

Weight: 600kg, Diameter 800mm. |

|

Feeding sheet part:

Automatic feeding reduces human resource costs.

Actively transport the sheet and reduce the load on the conveying servo motor.

Cleverly control the proximity switch to prevent the sheet from falling too quickly during transportation. |

|

Human-machine interface:

Controlled by microcomputer and programmable controller (PLC),

all action programs can be operated through the human-machine interface,

simple and convenient, 15-inch touch screen. |

|

Heater:

1. Vacuum insulation cotton is installed in the heater,

2. The furnace body is divided into two layers, |

|

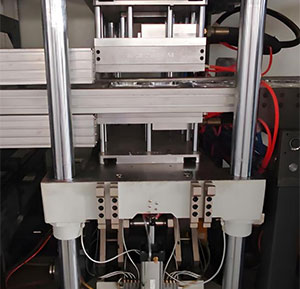

Molding station:

1. Mold changing auxiliary mechanism, using sliding guide rails

2. Adopting high-power servo motor drive, high precision, high efficiency and low noise. |

|

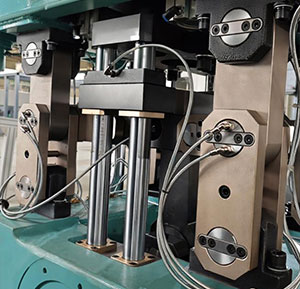

Molding mold:

The working principle is a combination of positive and negative pressure,

and some nylon plugs are used to assist stretching in the mold to make it have stronger molding ability.

There is cooling water in the mold cavity to speed up the cooling speed and make demolding easier. |

|

Guide head structure:

The workstation is supported by four columns (45# steel, hard chrome plated).

The integrated mold table (QT-600 steel) is made by a high-precision CNC milling machine.

Therefore, it is wear-resistant, stable, and accurate, which prolongs the service life of the equipment. |

|

A five-point-connecting-rod structure:

This structure design provides more stable operation and faster speed. |

|

Mold change structure:

The punching hole station has the same mold changing structure as the cutting station.Greatly reduce mold change time and labor costs, improve production efficiency and safety factor, and provide convenience for your diversified product chain. |

|

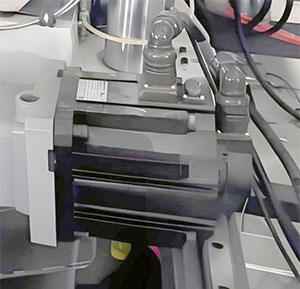

Servo motor:

The station mold closing, forming auxiliary stretching, and pull-tab parts are all driven by servo motors, which have fast speed, low noise, high precision, and high efficiency. |

|

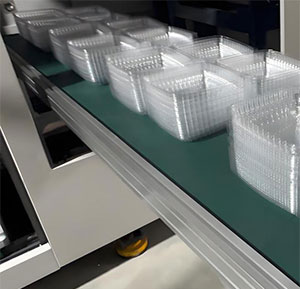

Servo-controlled conveyor belt:

Set conveyor belt parameters directly on the operation screen. |

|

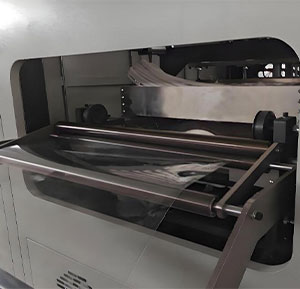

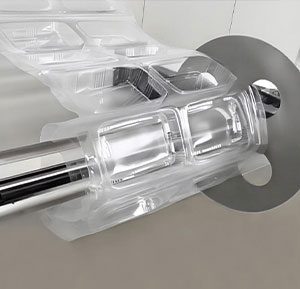

Rewinding waste of edge sheet:

Our multi-station thermoformers feature a winding unit with torque motor to efficiently collect the offcuts and wind them into a roll with one side retractable, which can be conveniently removed at the end of production.

This advanced waste management system improves operating efficiency and cleanliness, making multi-station thermoformers ideal for high-quality and sustainable production. |

|

Sheet Materials |

PP/PS/PET/PLA/PE/CPET |

Air Consumption |

4m³/min 0.5-0.8bar |

|

Sheet Thickness |

0.2-1.5mm |

Weight |

15500kg |

|

Forming Area |

730*610mm |

Total Installed Power |

185kw |

|

Width Of Sheet |

400-800mm |

Heating Power |

140kw |

|

Upper Forming Depth |

100mm |

Feeding Motor |

4.4kw |

|

Bottom Forming Depth |

130mm |

Control Forming Plug Motor Power |

4.4kw |

|

Max Speed |

45moulds/min |

Stacking Motor |

1.8kw |

|

The Longest Knife |

10m |

Winding Waste Of Edge Sheet Motor Power |

0.4kw |

|

Dimension |

12785*2350*2700mm |

Forming Motor |

5.5kw*2 |

|

Forming clamping force |

750kn |

Cutting Motor |

5.5kw*2 |

|

Punching clamping force |

750kn |

Punching Motor |

5.5kw*2 |

It can make some products which unable to be made in one station thermoforminging machine, like for example: PLA products, plastic lids or containers which has holes, the packing containers (fruit box, egg trays) with body and cover connected etc.

We have a 30-person after-sales team

30-day fast delivery, modular production

One-year warranty, lifetime maintenance

GET A QUOTE