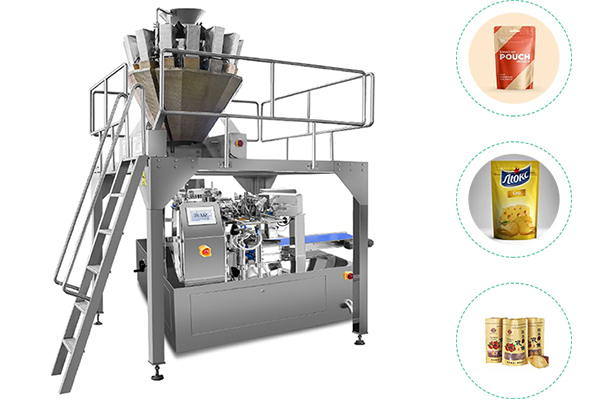

Pouch packing machine realizes functions such as bag feeding, bag opening, filling, sealing, and coding through different functional stations. It can be integrated with other automation equipment to form a complete automated production line, improve production efficiency and reduce labor costs. It is suitable for packaging various products such as powder, granules, liquids, flakes, blocks, etc.

The fully automatic pouch packing machine series has a variety of functions and can be matched with other ELEMOTION equipment to meet the packaging needs of different products.

Quickly change packaging bag specifications, and the width of the automatic bag feeding device can be automatically adjusted at one time.

Comply with the hygiene standards of food processing machinery. The parts on the machine that come into contact with materials or packaging bags are made of stainless steel or other materials that meet food hygiene requirements to ensure food hygiene and safety.

Easy to operate, using advanced PLC plus POD (touch screen) electrical control system, friendly human-machine interface, easy to operate, and can automatically adjust the angle and time of pneumatic components.

Sealing temperature monitoring function. If the heating tube or thermocouple is damaged, an alarm will be displayed on the touch screen.

Q:

What are the advantages of ELEMOTION bag packaging machine?A:

1.ELEMOTION packaging machine realizes high-speed and continuous packaging operation, which greatly improves the production efficiency. 2.ELEMOTION bag packaging machine adopts advanced technology and intelligent control system, which can accurately and stably complete the packaging process of the products. 3. ELEMOTION pouch packing machine also has the flexibility, which can be adjusted according to different product sizes, shapes and packaging requirements, to realize personalized packaging effect. It can be adjusted according to the size, shape and packaging requirements of different products to realize personalized packaging effect.Q:

What information should be provided to factor when customer choose?A:

1.Products type, solid products specific sizes 2.Bag sizes and type with pictures 3.Packing weight 4.Packing speed, capacity 5.Special requirements, such as filling Nitrogen, exhausting, zipper close, date printing 6.Power supply voltage, Frequency 7.Factory workshop, Height limited. 8.Powder —— caking condition, damp, solid mix 9.Liquid —— liquid temperature, paste or liquid, liquid volume, if need filing by twiceWe have a 30-person after-sales team

30-day fast delivery, modular production

One-year warranty, lifetime maintenance

GET A QUOTE