Packing Speed: 20 - 60 bags/min

Bag Width: 50 - 130mm

Bag Length: ≤ 180mm

Machine size: 1680mm*1356mm*1310mm (L*W*H)

1.Supports multi-station operation processes (bag loading, coding, bag opening, bag stretching, material feeding, straightening, and sealing), runs smoothly, effectively reducing labor costs and error rates.

2.Equipped with a bag inspection system that can automatically identify empty bags, ensuring that no material is fed and no bags are sealed without bags, thereby guaranteeing production stability.

3.Imported electrical components from Fuji, Japan, ensure long-term stable operation and reduce maintenance frequency.

4.Quickly change bag specifications. Different bag types can be changed in just a few minutes, improving production switching efficiency.

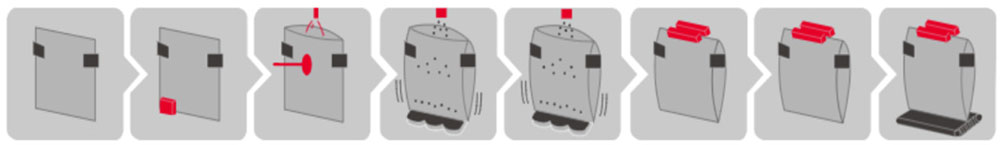

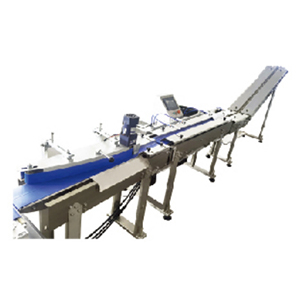

①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥material feeding ⑦bag pulling ⑧seal ⑨seal ⑩seal

Multi-Station Workflow

Smart Pouch Detection

Industrial-Grade Durability

Quick Changeover

Multilingual HMI

| Machine model | YDZDH-230A | YDZDH-260A | |||

| Equipment and materials | 304 stainless steel (part in contact with food) | ||||

|

Pneumatic components |

FESTO, Germany (standard parts), adek, Taiwan (non-standard parts) |

||||

|

Driving mode |

Mechanical transmission (cam gear lever full mechanical mode) |

||||

|

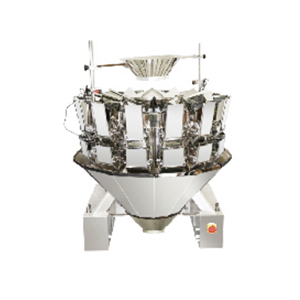

Measurement method |

Shrinkage cup metering, bowl feeding, combined scale, etc. (optional) |

||||

|

Applicable materials |

Candied pastries, melon seeds, peanuts, fried nuts, expanded products products in small bags and large bags, etc. (no vacuum pumping) |

||||

|

Workflow |

①Bag loading ②coding ③bag opening and bag supporting ④blanking i/down shock (optional) ⑤blanking ii ⑥reservation ⑦sealing i⑧sealing ii、Shaping |

||||

|

Sealing method |

According to the product, two seals can be used to ensure that the seal is beautiful and firm |

||||

|

Packaging speed |

20 packs~60 packs /min (depending on the product itself and the charge) |

||||

|

Packing bag materials |

Self standing bag, zipper bag, four side sealed bag, three side sealed bag, paper bag (surface coated with paper), etc |

||||

|

Bag specification |

W80mm*230mm L100mm*350mm |

W130mm*260mm L100mm*400mm |

|||

|

Total power |

Main engine power ≈4.5KW |

Main engine power ≈5KW |

|||

|

Gas consumption |

0.6m³/min |

||||

|

Driving power supply |

Three phase 380V 50HZ (non-national standard three-phase 380V 60HZ) |

||||

|

Machine shape |

1680mm*1356mm*1310mm (L*W*H) (excluding hoist) |

1800mm*1440mm*1310mm (L*W*H) (excluding hoist) |

|||

|

Machine weighi |

1.5T(Host) |

2T (Host) |

|||

|

Use environment |

Room temperature 10℃~40 ℃, 30~90%RH, no dew, corrosive gas, dust and other harsh environments |

||||

ELEMOTION automatic bagging packaging is suitable for the production of candied fruit cakes, melon seeds, peanuts, fried nuts, puffed products, small bags, large bags, etc. (without vacuum)

-1537.jpg)

.jpg)

-1537.jpg)

We have a 30-person after-sales team

30-day fast delivery, modular production

One-year warranty, lifetime maintenance

GET A QUOTE