Packing Speed: 105-120bags/min

Bag Width: 50-100mm

Bag Length: 60-180mm

The appearance design is reasonable, beautiful, efficient, energy-saving and environmentally friendly. The packaging speed depends on the product. Its core power cam is made of materials imported from Japan. After 21 processing steps, the surface layer is wear-resistant and elastic. The cam is easy to maintain and clean, has a service life of up to fifty years, and comes with a lifetime warranty.

All parts of the equipment comply with relevant national standards and are mainly equipped with imported electrical components. All parts that come into contact with food or packaging are made of food-grade 304 stainless steel or 316 stainless steel, as well as other materials that meet food hygiene requirements. Ensure food hygiene and safety.

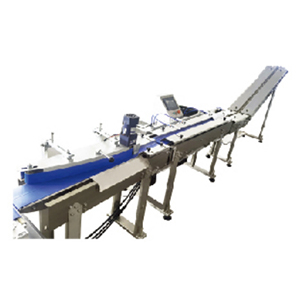

The equipment is easy to operate and adopts advanced PLC and POD electrical control systems and mechanical transmission systems to realize automatic bag taking, manual feeding, automatic loading, automatic vacuuming, automatic sealing, and automatic unloading.

The vacuum air-holding device of the equipment is made of synthetic materials jointly developed by our company and Germany, which can achieve zero friction and zero wear during the vacuum packaging process, and provides a lifetime warranty.

The equipment has its own lubrication system with a built-in lubricating oil tank. The system can recover and filter excess oil to achieve recycling and extend the service life of the equipment.

Mechanical drive

CAM lifetime warranty

Bag width automatic adjustment

Gas plate lifetime warranty

Automatic lubrication system

Aviation aluminum carving and milling vacuum chamber

●PLC control system ●Blanking detection ●Output system

●Automatic alarm ●Bag mouth cleaning ●Bag loading device

●Vacuum system ●Bag opening device ● Heat sealing control

● Bag opening detection ●Temperature monitoring ●Unloading device ●Water cooling device

|

Model number |

YD1016-1018 |

YD1014-1018 |

YD1012-1018 |

YD1012-1318 |

YD1010-1318 |

|

Packing bag material |

Aluminum foil, four-sided sealing flat bags, vertical bags, zipper bags, paper bags and other composite bags |

||||

|

Packing bag specification |

W:50-100mm L:60-180mm |

W:50-100mm L:60-180mm |

W:50-100mm L:60-180mm |

W:55-130mm L:60-180mm |

W:55-130mm L:60-180mm |

|

Packing speed |

105-120bags |

90-105bags |

80-95bags |

75-90bags |

50-65bags |

|

Driving mode |

Mechanical transmission (CAM gear bar full mechanical mode) |

||||

|

Main engine weight |

2.8T |

2.5T |

2.4T |

2.5T |

2.2T |

|

Air consumption |

≥0.8m³/min |

≥0.8m³/min |

≥0.8m³/min |

≥0.8m³/min |

≥0.8m³/min |

|

Power |

≈11KW |

≈9KW |

|||

|

Driving power supply |

380V three-phase five wire 50HZ |

||||

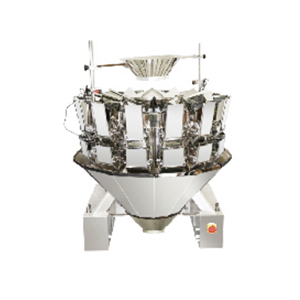

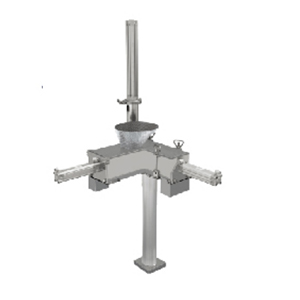

YD1016-1018 Automatic Vacuum Packaging Machine is equipped with an egg feeder, suitable for producing egg products, including spiced eggs, quail eggs, fish balls, beef balls, vitality eggs and other products, mainly in spherical or egg shapes.

-1537.jpg)

.jpg)

-1537.jpg)

We have a 30-person after-sales team

30-day fast delivery, modular production

One-year warranty, lifetime maintenance

GET A QUOTE