Packing Speed: 20 packs~40 packs/min

Bag Width: 180 - 380mm

Bag Length: ≤ 450mm

Machine size: 1890mm*1665mm*1370mm(L*W*H)

1.Develop single-chamber and double-chamber vacuum packaging machines to meet different customer needs, significantly improving production capacity and efficiency.

2.Suitable for packaging various types of cooked foods, sauces, pickled meats, frozen seafood, and other products with high preservation requirements.

3.Easy to clean, vacuum chamber can be washed

4.Equipped with safety protection design and anti-misoperation sensors to ensure the safety of operators.

Double-Vacuum chamber

Cold chain-specific

Easily cleaned

Safety protection

Highly automated

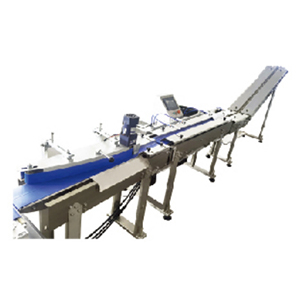

①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥bag pulling ⑦seal ⑧seal

|

Machine model |

YDZDH-300A |

YDZDH-380A |

|

Equipment and materials |

304 stainless steel (part in contact with food) | |

|

Pneumatic components |

FESTO In germany,SMC in japan(standard parts),adek in taiwan (non-standard parts) |

|

|

Driving mode |

Mechanical transmission (cam gear lever full mechanical mode) |

|

|

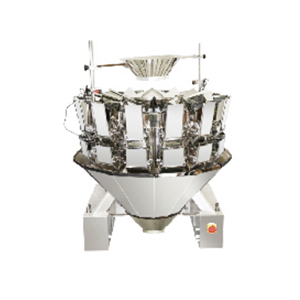

Measurement method |

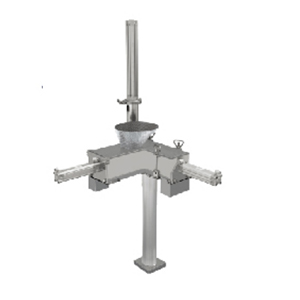

Bowl feeding,combined scale,etc.(optional |

|

|

Applicable materials |

Large pieces of tripe, fried nuts,big red dates, puffed products, large bags in small bags, etc.(no vacuum pumping) |

|

|

Workflow |

①Bag loading ②coding ③bag opening and bag supporting ④blanking i/down shock (pioral)5 bankng i6 resenaion (7 seaingi 8 seaing i、Snapng |

①Bag loading ②reserved space ③bag opening and bag supporting 4)blanking i(Sheat seal(6 heat seal |

|

Sealing method |

According to the product,two seals can be used to ensure that the seal is beautiful and firm |

|

|

Packaging speed |

20 packs~40 packs/min (depending on he prouct isef and the cherge |

10 packs~30 packs/min(cependng on the prctct isef and the charge |

|

Packing bag materials |

Self standing bag,zipper bag,four side sealed bag,three side sealed bag,paper bag (surface coated with paper), etc |

|

|

Bag specification |

200mm*450mm W180mm*300mm L200mm*450mm |

200mm*450mm W240mm*380mm L200mm*450mm |

|

Total power |

Main engine power ≈5KW |

|

|

Gas consumption |

0.6m³/min |

|

|

Driving power supply |

Three phase 380V 50HZ(non-national standard three-phase 380V 60HZ) |

|

|

Machine shape |

1890mm*1665mm*1370mm(L*W*H)(excluding hoist) |

1850mm*1950mm*1400mm(L*W*H)(excluding hoist) |

| Machine weighi | 2T(Host) | |

| Use environment | Room temperature 10 ℃~40 ℃, 30~90%RH, no dew, corrosive gas,dust and other harsh environments | |

ELEMOTION's Automatic Vacuum Premade Pouch Machine is suitable for producing large pieces of tripe, fried nuts, large red dates, puffed products, large bags in small bags, etc. (no vacuuming required)

-1537.jpg)

.jpg)

-1537.jpg)

We have a 30-person after-sales team

30-day fast delivery, modular production

One-year warranty, lifetime maintenance

GET A QUOTE