Packing Speed: 55-70bags/min

Bag Width: 80-160mm

Bag Length: 80-270mmMechanical drive

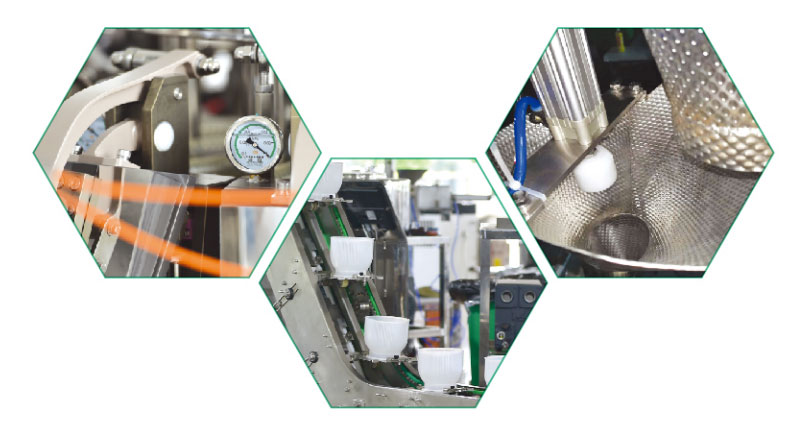

1.ELEMOTION packaging series has multiple functions and can be used with other equipment to meet the packaging needs of different products.

2.Customized packaging solutions tailored to the specific characteristics of each customer's products, compatible with liquids, granules, pastes, and solid materials such as condiments, frozen meat, ready-to-eat foods, and pet food. A single production line can accommodate multiple product requirements, thereby reducing investment costs.

3.The entire line supports continuous high-speed operation, completing 30-80 bags per minute.

4.Solve problems such as low efficiency and high error rates in manual filling and sealing, ensure that each package is consistent, attractive, and hygienic, and enhance brand image and market competitiveness.

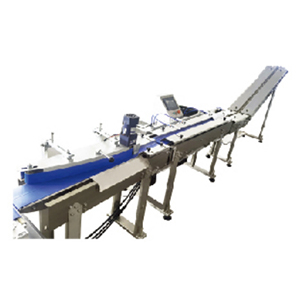

5.Integrated fully automatic vacuum packaging production line, suitable for large-scale food processing enterprises, realizing full process automation of material conveying, weighing, bagging, vacuum sealing, and finished product conveying, significantly improving overall production efficiency and automation level.

CAM lifetime warranty

Bag width automatic adjustment

Gas plate lifetime warranty

Automatic lubrication system

Aviation aluminum carving and milling vacuum chamber

Continuous High-Speed Packaging

Intelligent Control System

Labor Cost Reduction

Multi-format Bag Support

Highly automated

|

Model number |

YD1012-1627 |

YD1010-1627 |

YD0810-1927 |

YD0810-2331 |

YD0810-2837 |

|

Packing bag material |

Aluminum foil, four-sided sealing flat bags, vertical bags, zipper bags, paper bags and other composite bags |

||||

|

Packing bag specification |

W:80-160mm L:80-270mm |

W:80-160mm L:80-270mm |

W:90-190mm L:160-270mm |

W:120-230mm L:160-310mm |

W:160-280mm L:160-370mm |

|

Packing speed |

55-70bags |

45-60bags |

45-60bags |

35-50bags |

18-40bags |

|

Driving mode |

Mechanical transmission (CAM gear bar full mechanical mode) |

||||

|

Main engine weight |

2.6T |

2.3T |

2.6T |

3T |

3.2T |

|

Air consumption |

≥0.8m³/min |

≥0.8m³/min |

≥0.8m³/min |

≥0.8m³/min |

≥0.8m³/min |

|

Power |

≈9KW |

≈10KW |

≈12KW |

≈13KW |

|

|

Driving power supply |

380V three-phase five wire 50HZ |

||||

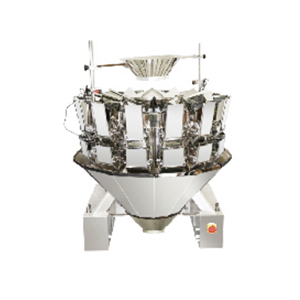

Automatic Vacuum Food Packaging Production Line is suitable for products that are mainly composed of multiple materials or cannot be automatically measured, such as material packages, cooked food products, healthy vegetables, beef packages and other products, to achieve manual measurement and automatic unloading. In the case of workshop height restrictions, it is usually used in combination with an electronic combination scale as a transition link to reduce the overall height of the equipment.

-1537.jpg)

.jpg)

-1537.jpg)

We have a 30-person after-sales team

30-day fast delivery, modular production

One-year warranty, lifetime maintenance

GET A QUOTE