Bag size:L: 80mm*300mm W:80mm*200mm

Packaging speed: ≤ 90bags/min

Machine size: 1500mm*1035mm*1850mm(L*W*H)

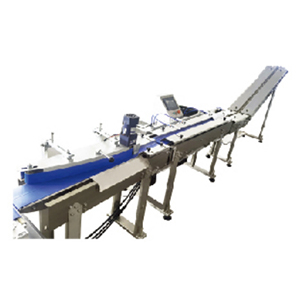

The Machine And Metering Configuration Can Automatically Complete The Whole Packaging Process Of Metering,Feeding,Filling And Bag Making, Date Printing,Inflation(exhaust)And Finished Product Transportation, And Automatically Complete Counting

1. Equipped With Safety Protection To Meet The Requirements Of Enterprise Safety Management;

2. Intelligent Temperature Controller Is Adopted,With Accurate Temperature Control To Ensure Beautiful And Flat Sealing;

3. PLC Servo System, Pneumatic Control System And Super Large Display Touch Screen Are Used To Form The Driving Control Core To Maximize The Control Accuracy,Reliability And Intelligence Of The Whole Machine;

The Touch Screen Can Store The Packaging Process Parameters Of A Variety Of Different Products,Which Can Be Used At Any Time When Changing Products Without Resetting;

It Is Equipped With Guarantee Display System,Which Can Help Eliminate Faults In Time After Faults Occur;

Pillow Bags And Perforated Bags Can Be Made According To Customers' Needs;

Single Belt Film Transportation,Fast And Stable,Low Friction And Low Loss.

| Mode | YD-420 |

| Bag size | L:80mm*300mm W:80mm*200mm |

| Packaging speed | ≤90 Packet/min |

| Power supply and power | AC220V,50~60HZ,3.0KW |

| Compressed air consumption | 6~8Kgf/cm²,0.15m³/min |

| Overall dimension | 500mm*1035mm*1850mm(L*W*H) |

It is suitable for all kinds of leisure food, meat products, seafood, fruits and vegetables, pickles, chilled meat, medical products, hardware components, medical devices,etc.

-1537.jpg)

.jpg)

-1537.jpg)

We have a 30-person after-sales team

30-day fast delivery, modular production

One-year warranty, lifetime maintenance

GET A QUOTE